Collaborative Robot-based Palletising Cells

COPALLETIZER

The most advanced collaborative solution on the market

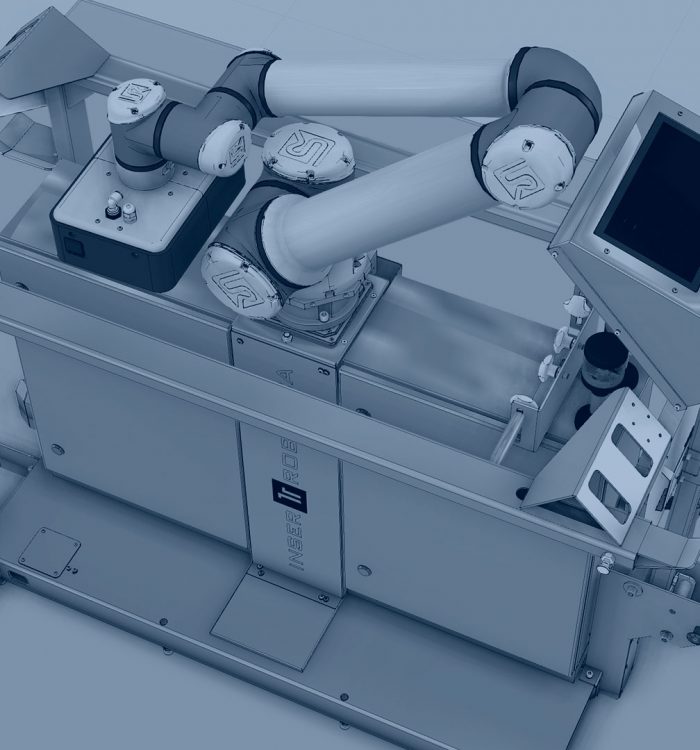

Automated palletising based on Collaborative Robots

The most versatile and productive cobot-based palletising option

We present our standard collaborative palletising cell as a product which is distinctly different from our usual bespoke palletising solutions.

We have enhanced all the benefits that incorporating this type of robot entails, taking both its portability and user-friendliness to a higher level. And we have not stopped there. This cell is the easiest to configure and offers the highest real productivity.

Moreover, it can be adapted to both multinational companies already aware of the benefits of process automation, as well as SMEs in need of a technologically advanced option at an affordable price.

What sets it apart from other collaborative options?

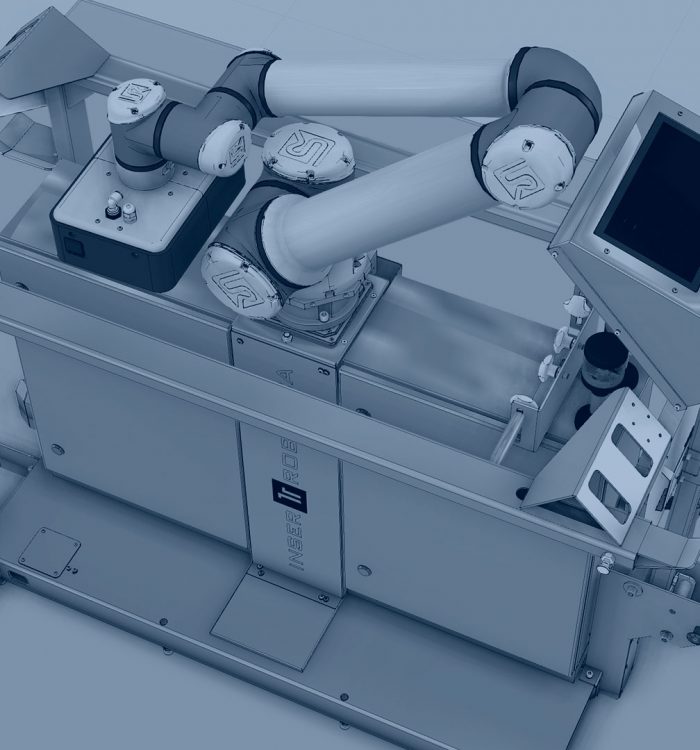

Optimised scope and paths, unparalleled modularity, a programming wizard and certified safety

Collaborative Arm

This type of robot includes sophisticated safety functions combining hardware and software to ensure safe operation.

Thanks to their reduced weight they can stand on simpler frames and increase their scope with lifting columns in a cost-effective way.

Programming wizard

State-of-the-art path planning algorithms calculate the best path for each box. The robot palletises up to 20% faster and 30% smoother than traditional programming.

*This is an option not included in the standard package.

Collapsible frame

Modularity

Our Plug&Play modules for transporting boxes and storing cardboard are extremely easy to install. They can be placed on either side of the cell to adapt to the available space.

All modules can be moved using a pallet truck to facilitate setting-up.

Lifting column

Collaborative robots have a limited scope that prevents the palletising of boxes at a certain height.

This height will depend on the size and the weight of the boxes. To increase the scope, lifting columns can be integrated to allow palletising up to a height of 2.2 m.

Gripper

Since the load capacity of collaborative robots is quite low, very light tools are required. Our design consists of an aluminium frame and a 3D-printed casing.

Certified safety

Although every element integrated is considered collaborative, the risk of moving loads above shoulder height must be taken into account. When the robot is palletising above a height of 1.5 m, two safety scanners are integrated.

Laser scanner

Rental/Pay-per-Use Options

Facilitating access to SMEs or companies with production seasonality.